What are Nuts and Bolts?

What are nuts and bolts?

What are nuts and bolts? To begin with simple definitions, nuts are internally threaded, thick-edged fasteners. They're usually hexagonal in shape and designed to tighten or assemble with at least, but not limited to, two components. They coordinate with bolts,which are externally threaded shafts of varying lengths and thicknesses. This is because the six sides make it easy to turn. It only takes a one-sixth turn for the nut to reach the next flat parallel. A nut with fewer sides takes more time to install. Other shapes are available for specific needs and applications.

What are different types of nut?

There are many types of nuts, all with specific uses. Some of the most popular types of nuts include: hexagon, domed, square, pentagon, flat and locking nuts. Tools can grab hex nuts from all angles to tighten. If necessary hex nuts can even be installed by hand. Many different bolt heads incorporate a hex design.

Domed nuts have bolt heads which are difficult to wrench externally, which adds a level of security. Square nuts enable an easy grip for wrenches for tightening nuts.

Designers create pentagon nuts (also know as shear nuts) to resist tampering by not accommodating torx and hex tools.

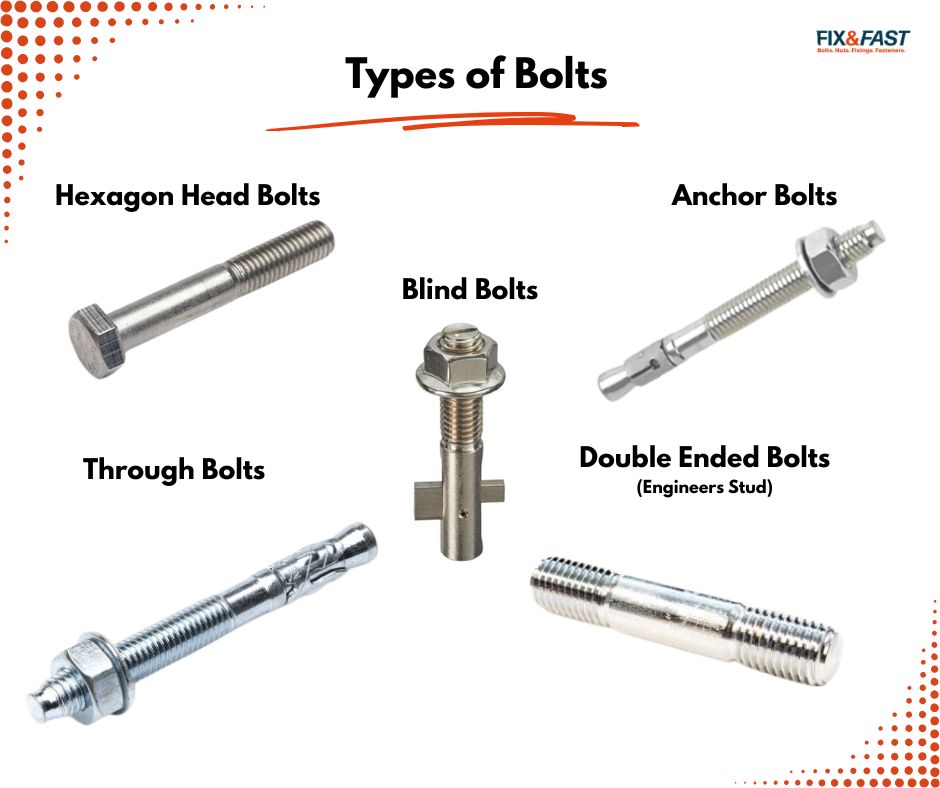

What are different types of bolt?

Bolts are very useful in construction. Some popular types of bolt include: anchor, blind, double end, and hex bolts.

Construction professionals use anchor bolts to secure a structural components into a concrete, and sometimes may use resin to ensure the fixing is strong.

Double end bolts are bolts with threads on both ends, also called stud bolts.

We can characterise hex bolts by its six-sided head and there are many different types of hex bolts. Typically used in machinery and construction applications and available fully or partially threaded.

Finally, flat headed bolts are countersunk, which enables them to save space on applications.

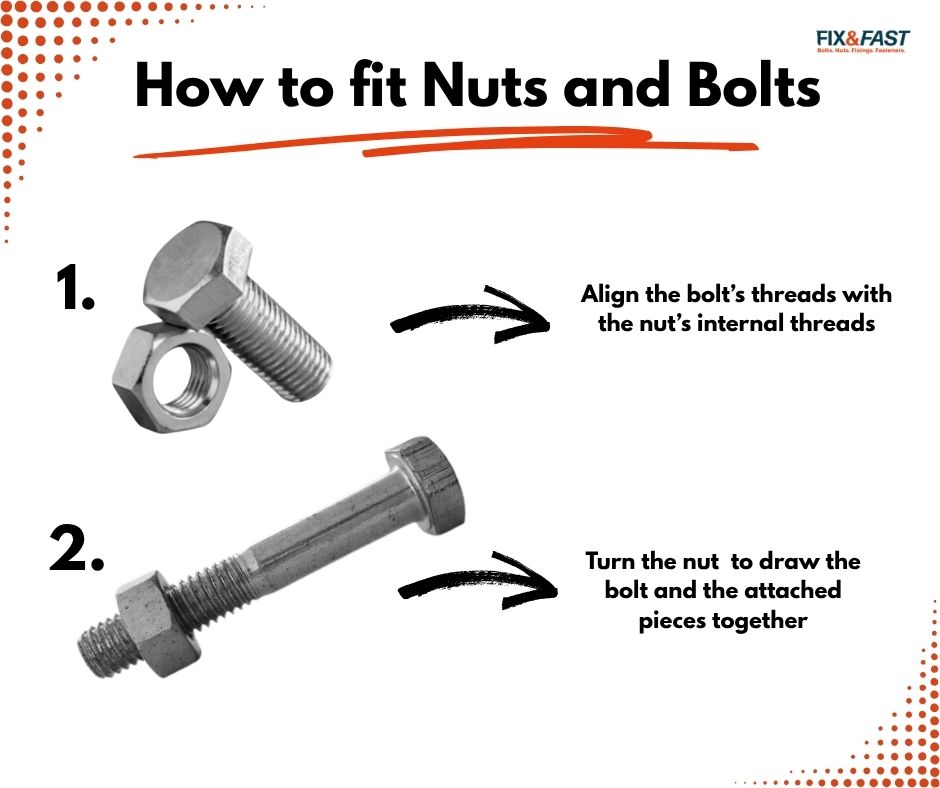

How are nuts and bolts fitted?

Slide the washer onto the end of the bolt and push it as far as it will go until it reaches the head of the bolt.

Take the bolt with the washer in hand and push the threaded shaft through both holes in the pieces of wood. Take another washer and place it on the threaded shaft protruding from the second piece of wood.

Push the washer all the way up until it is flush with the wood material. Finally, complete the fastening process by using a wrench that fits the size of the nut.

Place the wrench on the nut and tighten it firmly so there is no wiggle room between the nut and the washer.

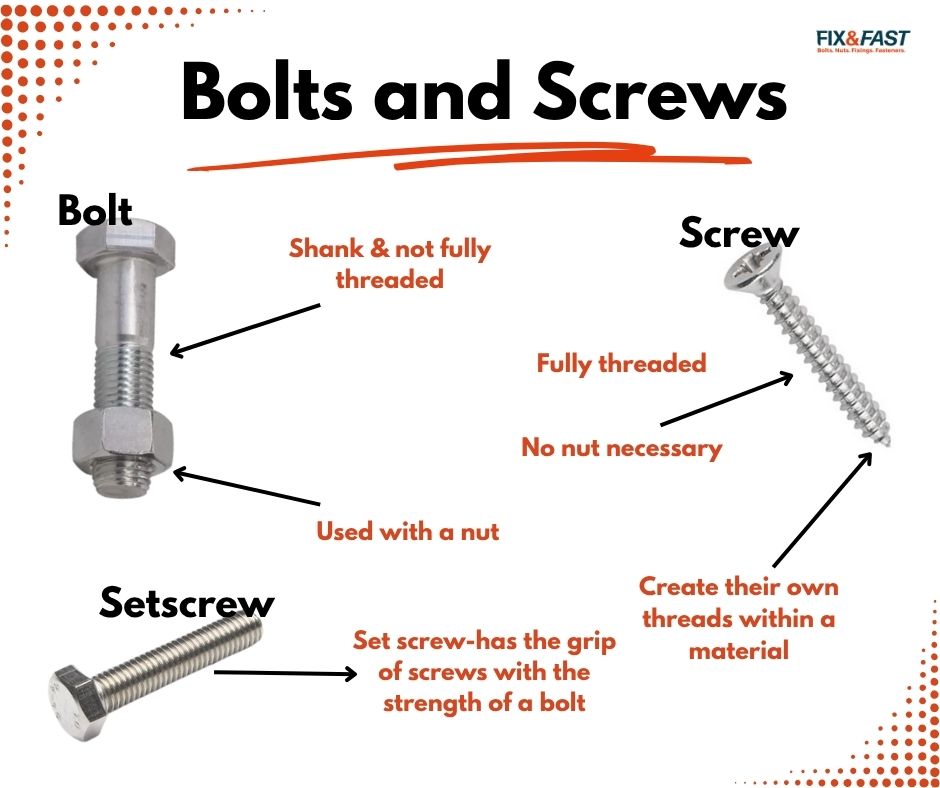

What is the difference between a bolt and a screw?

In short, bolts usually have higher shear strength, but screws usually have a tighter grip.

Both of these are threaded fixings and have a head for tightening the fastener. However, they differ significantly in design, functionality, and application.

One of the most obvious distinctions lies in the threading: manufacturers typically make bolts partially threaded, with a plain shank portion, and they almost always make screws fully threaded, right up to the head.

This difference impacts their strength and how they interact with materials: the plain section of a bolt adds shear strength, making it less likely to bend under stress.

Fully threaded screws provide a tighter grip, making them ideal for applications where precision fastening is required. Some woodscrews do have a small shank - this can help pull the two matreials together.

Fully threaded bolts, also called set screws, blur the line further, offering the gripping advantage of screws with the strength of bolts.

At Fix and Fast, we stock a wide range of strong, high quality nuts and bolts, which are massively useful in construction. FRScott and their 80 years of fixing and fastener expertise support us, and Trustpilot rates us as Excellent.

Do you need advice or guidance on something more specific? Get in touch - we are more than happy to help.

sales@fixandfast.co.uk

01482 324731